Midwest Team Thanked for Getting the Job Done SAfely

[June 10, 2024] Shout out to the Menomonie, WI operations for no recordable injuries since December 2022. According to George Loudermilk, Midwest Operations Manager, the 85-person crew’s 19-month run is down to: “Making sure people are aware of the hazards in their surroundings and the equipment they work with. We encourage everyone to watch out for each other and make safety equal to throughput and quality.”

“We want people to understand that Bright Wood’s safety policies and procedures are there to protect them and provide them with a safe work environment,” George said.

The busy Menomonie operations include a custom-sized extension jamb line, a paint line, and two warehouses. Every day, the team delivers components in the exact order they will be used to a nearby customer’s window assembly line. The Freitag location ships a truckload every 1-1/2 hours, averaging 50-plus outbound loads weekly. The Walton facility ships 45 truckloads weekly.

“We rolled out the STAR program (Safety Training Awareness and Responsibility) earlier this year,” Kim Miller, Menomonie Plant Manager, said. “Participation has been good, and people have become more aware of their surroundings.”

“I have heard a lot of positive comments about the high-vis vests from people on the floor along with truck drivers and vendors,” Kim said. “Everyone is very pleased with the focus on safety.”

All Menomonie team members received a $100 safety award bonus and a water bottle as a thank you and encouragement to keep up the good work.

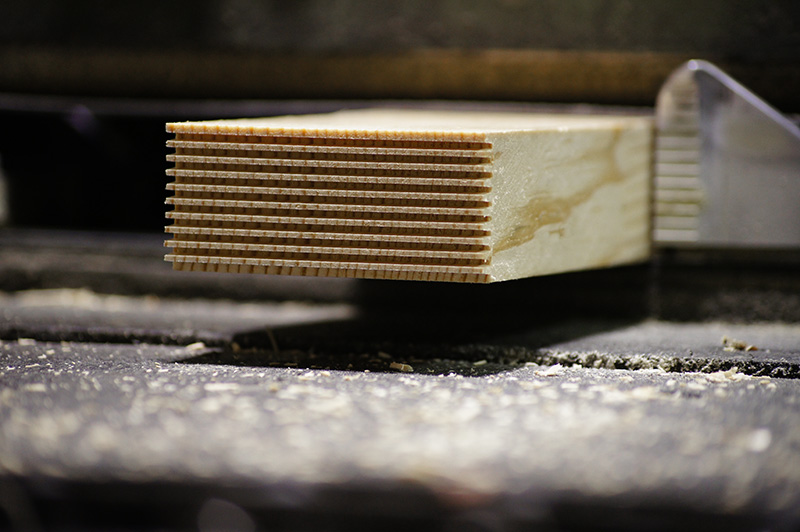

Product Spotlight: MDF Mouldings

[May 7, 2024] MDF mouldings transformed the market when they were introduced in the 1980s. Designers and homeowners quickly realized they could use larger profiles and more combinations to create new looks while remaining within their budget. Installers were won over by the ease of working with a uniform product without the grain and knots of solid wood.

Madras Plant 14 has been manufacturing primed MDF mouldings since 1997. In 2023, we shipped 216 mixed truckloads of solid hem-fir and domestic or radiata pine, raw or primed fingerjoint, and MDF mouldings.

Note: Bright Wood only sells mouldings to millwork distributors. If you are a homeowner or contractor, visit your local lumber yard or home improvement store to experiment with moulding combinations.

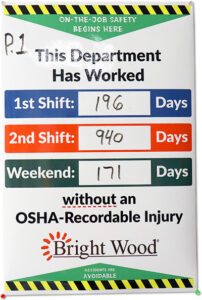

Madras Plant 1 Swing Is a Safety STAR

[March 29, 2024] Well done to Madras Plant 1 swing shift for working 942 days (and counting) without a recordable injury as of March 29.

“We pay attention to what we do,” Sam Cabral, Swing Supervisor, said. “We use the STOP* and STAR** cards and all the available tools.”

“We do get a lot of STAR cards, and we are always pushing for more,” Miguel Sevilla, Swing Lead, said. “People are well aware of the dangers and watch out for one another.”

“It also helps that most have been here for a while, so they know what to do,” Miguel said. “When we first started, everybody and this plant were brand new, so it was harder.”

*STOP: Safety Training Observation Program

**STAR: Safety Training – Awareness and Responsibilities

Safety Is the Fashion Statement

[March 14, 2023] Thanks to all the Bright Wood people who quickly got on board with the new Personal Protective Equipment (PPE) policy requiring all associates and visitors to wear high-visibility attire while on company property. The only exceptions are offices and breakrooms.

High-vis clothing is one more tool for preventing workplace accidents and injuries. That pop of fluorescent orange and yellow makes people stand out in busy work zones and low-light conditions.

So, when you put on your high-vis gear before you get out of your car, know that you are making a difference.

P.S. Thanks to our models Jeremy Ross and Terrie Heflin of the Redmond Saw/Sand Plant. High fashion at its best.

New Infeed Is a Block Party for Downstream Operations

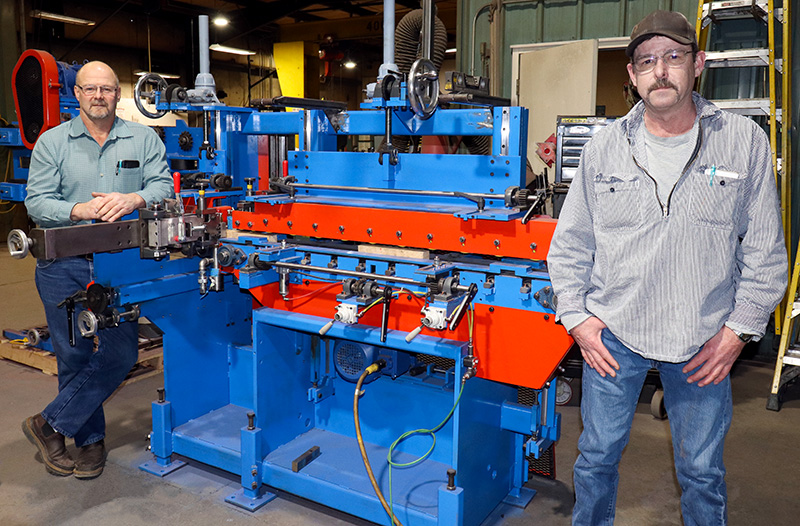

[March 6, 2024] A new infeed at the Culver stud line is ensuring a steady supply of on-grade blocks to the fingerjoint line. The Bright Wood designed and built system consists of one scanner, three automatic cut-off saws, and sorting belts and bins.

All inbound material goes through the USNR AddVantage scanner. “The scanner’s function is to grade out defects and send us good wood,” Jesus Cohetzaltitla, Culver Site Manager, said. Narrow and off-grade lumber is diverted before it goes any further. “We catch it before we cut it,” Jesus said.

The scanner feeds wood to three Ultimizer automatic chop saws. “We programmed the saws, and they do their thing,” Jesus said. Each saw can cut 100 lineal feet per minute.

“The belts accumulate enough blocks so that we always have a steady stream of material to process,” Jesus said. The stud line’s key performance measures for throughput, waste, and rework have all improved since the upgrade.

Prineville Recognized for Safety Leadership

[February 15, 2024] The Prineville site celebrated 16 months and counting without a recordable injury on February 13. “You are the example used across the company to show what can be accomplished,” Casey Jackson, Operations Manager, told the Prineville crew. “We’re here to acknowledge all the great things you did to get to this level. It took a lot of everyday effort on everyone’s part to accomplish this, and it is something to be proud of.”

The 53-person site dined on prime rib and grilled chicken, potatoes, green beans, salad, and cake prepared by Barney Prine’s Steakhouse. Bright Wood surprised each team member with a check for $100 as a thank you for a job well done.

Site Manager Kim Dixon credits more guarding and participation in STAR (Safety Training Awareness and Responsibility) for the turnaround.

“A major focus on safety made the difference,” Prineville Safety Manager Monica Bryant said. “It started at the top, and the entire crew joined in. More people participated in the STAR program than ever before, and we held each other accountable for safety violations. Our safety gains came down to teamwork.”

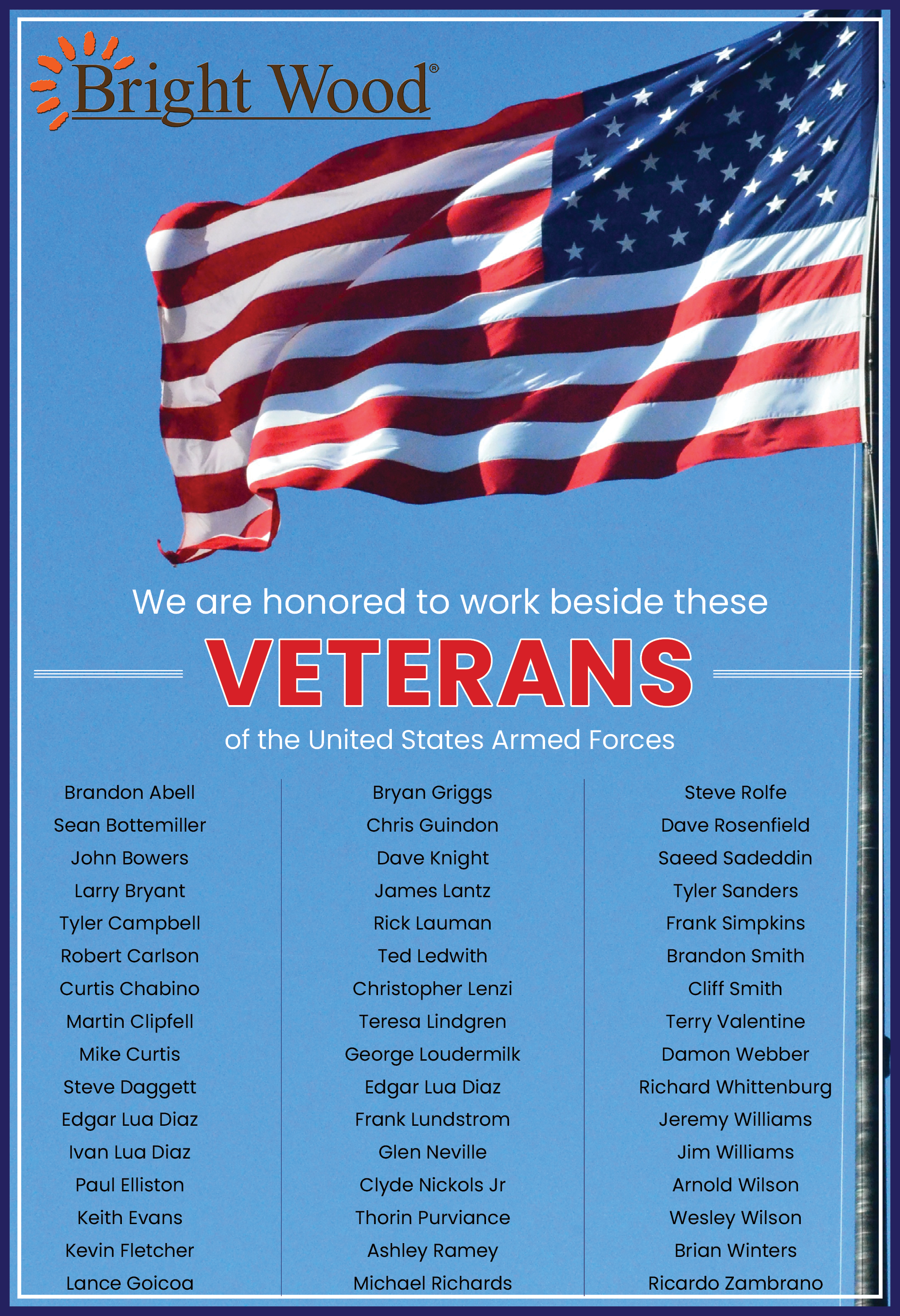

Thank You Veterans

[November 9, 2023] This Veterans Day, Bright Wood would like to thank the men and women who stepped up to protect and serve our country. We are safer because of you.

We are also grateful for the many veterans who brought their skills, integrity, and can-do attitude to Bright Wood. It is an honor to work beside you.

Please let us know via the Contact Us page if we are missing any veterans from this list. Include the individual’s name, site, and plant/department.

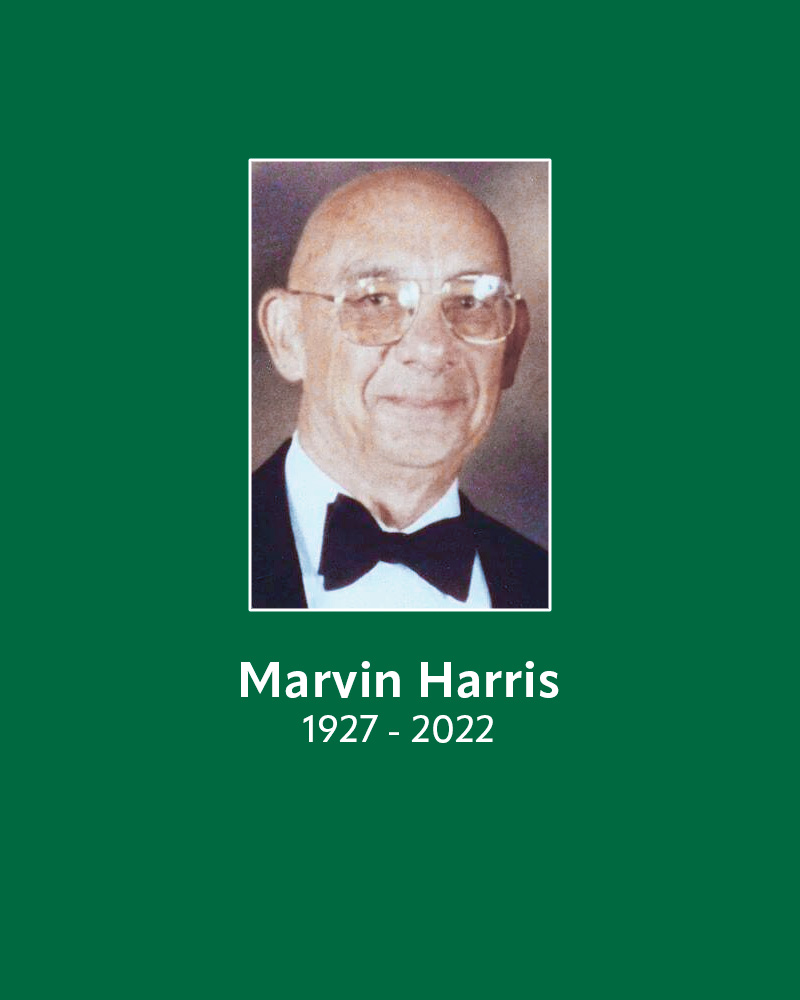

Millwork Pioneer Leaves $3.25 Million Legacy for Orphans

[October 25, 2023] Check out this article about local millwork legend Marvin Harris by Suzanne Roig of The Bulletin. Harris worked hard and made a difference in our industry and local community. Then, he kept it going by leaving a legacy for orphans in Israel.

Job Creator

Harris co-owned COIN Millwork in Prineville, OR, with Leonard Wilkinson. It was the US’s largest secondary wood products manufacturer during its heyday in the 1960s and ‘70s. About 1,000 people made door and window frames in the 13-acre facility, all under one roof.

Former COIN employee and now the Prineville City Manager Steve Forrester (who also worked for Bright Wood in the 1990s) recalled the mill as a family-friendly workplace that welcomed women. “He broke some of those barriers there,” Forrester said. “He had a lot of moms working alongside their husbands. He made that industry so strong. It employed so many people in our community for a long time. He was instrumental in building that business. It was a major employer of Crook County for 50 years.”

Home Builder

Harris started Marv Harris Enterprises Inc. after he and Wilkinson sold the mill in 1977. Harris bought and sold real estate and built homes with his new business venture. Harris has been called a visionary for his support of new housing developments in Prineville as well as youth and adult sports.

Benefactor for Orphans

When Harris died in September 2022 at 95, he left the bulk of this estate, approximately $3.25 million, to the Jewish Federation of Greater Portland. In his will, he specified that the federation distribute the interest income from his endowment -- which should amount to around $150,000 per year -- to support orphans in Israel in perpetuity.

Lots of Food & Fun at the Bright Wood Picnic

[August 9, 2023] Thank you to all the Bright Wood families who spent Saturday with us at the company picnic. As CEO/President Dallas Stovall said, it was a day to celebrate the people who have contributed to Bright Wood’s success over the last 63 years.

Dallas told the story of a potential customer who was on the fence about Bright Wood as a supplier until they recently visited. After walking through the plants, watching the crew work, and talking to folks – the customer was impressed by how much Bright Wood people cared. The customer placed their first order shortly afterward.

The picnic was a day to relax, play together, and meet one another’s families. There was lots to eat with five food vendors and do with three bouncy houses, a mechanical bull, a photo booth, face painting, a balloon artist, the kids’ races, and a watermelon eating contest. Twenty-seven teams competed in the picnic’s first cornhole tournament, and the long-standing salsa contest was as spicy as ever.

Watch the News For Bright Wood People page for more picnic tidbits and photos.

Why We Crave Mint This Time of Year

[July 25, 2023] The shipping shed next to the Madras main office is more than just a shed. It is a little piece of local history.

Before Bright Wood purchased the building and land in the late 1980s, it was known as the “Jasa Mint Still.” Local farmers brought their harvest here to have their “mint mash” distilled into peppermint oil. The Madras variety was known for its strong taste and smell, which people working next door in the Bright Wood office and plants could attest to.

Oregon still leads the U.S. in peppermint production, growing nearly 35 percent of the national total, but demand has tapered off since the introduction of artificial mint flavoring. Carrot seed has taken its place, with Jefferson County farmers supplying approximately 55 percent of the domestic and 45 percent of the global carrot seed markets.

Nowadays, the former Jasa Mint Still is a busy hub for outbound millwork shipments. Bright Wood’s construction department is preparing it for the next 100 years with new framing and siding, using Douglas Fir 2x6 engineered studs manufactured by Madras Plant 15.

Madras VA Weekend Shift Celebrates First Anniversary

[July 7, 2023] Value-Added’s weekend shift celebrated its first anniversary today. We thank them for building this new shift from the ground up and making it successful. Their hard work allowed Bright Wood to capitalize on the rising demand for window components without compromising quality.

“These folks have demonstrated perseverance, dedication, and quality work in this initial year,” said Mike Curtis, Madras VA Weekend Shift Supervisor. “I look forward to seeing how they best their record in year two.”

Today the VA weekend shift consists of 20 people; 14 have been there since day one. Mike is looking for two more people to join the team so they can run one more line.

Later this year, the VA group will also be staffing weekend shifts in Madras Plant 7 and Plant 5. Let Personnel know if you’d like to work three days a week and have four days off with full benefits.

Prineville Crew Recognized for Safety Performance

[June 30, 2023] Bright Wood CEO/President Dallas Stovall personally thanked each member of the Prineville team for their safety performance on June 27. The 59-person site has not had a recordable injury since September 22, 2022.

The site celebrated the milestone with a pizza lunch, and managers gave everyone a water bottle to help them stay hydrated during the summer heat.

Way to go, Prineville, and please keep this good thing going.

New Weekend Shift Nails Throughput Goals

[June 9, 2023] Madras Plant 1’s new weekend shift is already holding its own just three months after startup. They’ve increased the optimizing plant’s capacity and, in doing so, relieved pressure on the day and swing shifts (and other cut plants, too) by achieving their throughput goals so quickly.

“With the help of key individuals willing to transition to the weekend shift, we were able to ‘hit the floor running,’” said Homero Lopez, Madras Plant 1 Manager. “The weekend shift is already up to par with what we run on the other two shifts.”

60-Year-Old Tuition-Assistance Program Still Helping Bright Wood Families Today

[May 19, 2023] Bright Wood’s Children’s Educational Tuition Assistance Program (CETAP) provides financial assistance for post-high school education ranging from college to trade school for employees’ dependent children.

The company has distributed over $1 million in CETAP funds since the early 1960s when founder Carl Peterson established the program.

Contact Bright Wood’s Personnel Department at 541-475-7799 between 7:30 a.m. and 4:30 p.m. to learn more and apply.

Gerardo Penaloza Carlon Takes First In WWPA Lumber Grading Contest

[May 12, 2023] Madras Plant 15’s Gerardo Penaloza Carlon won first place in the grading competition at the Western Wood Product Association’s (WWPA) meeting on May 6 in Yakima, Washington.

Gerardo was up against certified graders and experienced wood people from Oregon and Washington to see who could correctly grade 50 boards of varying species.

This was only Gerardo’s second competition, but he has been preparing for 25 years. He learned to grade as a cutter and then a rip saw operator in Madras Plant 8. His skills only got better when he transferred to the brand-new Madras Plant 15 in 2016. Today Gerardo is the lead in the engineered dimension lumber plant.

Sales’ Lonnie Ramey Retiring After 37+ Years

[April 26, 2023] Longtime Bright Wood salesperson Lonnie Ramey is retiring on Friday, April 28. After a 37-plus year run, he will hand millwork and distribution sales to Tara Williams.

Lonnie’s first job at Bright Wood was feeding a moulder in Plant 5 in 1985. Two years later, he joined the Sales Department. “I’ve always enjoyed working with people to make their lives/jobs easier by solving any product problems they may have,” Lonnie said.

“Anytime you are dealing with a lot of customers directly, there will be challenges,” Lonnie said. “But because Bright Wood produces very high-quality products and backs them with service, that removes many of the sales challenges that come and go.”

“There are few people in this world who can honestly say that they enjoy their job,” Lonnie said. “Most people work as a means to live and have a roof over their heads. Because of Bright Wood, I’ve had a job that I can truly say I have enjoyed.”

“After working with Lonnie for over thirty years, what stands out to me is his ability to listen to his customers, assess the situation, and put together a plan that meets the needs of both the customer and Bright Wood,” Carl Lindgren, Sales Manager, said. “Lonnie has worked hard to cultivate honest relationships that stand up to the challenges we face every day.”

Thanks to Lonnie for growing and maintaining Bright Wood’s rock-star stable of millwork and distribution customers. We wish you the best for retirement.

Third Group of Managers Graduates from COCC's Leadership Lab

[March 21, 2023] Congratulations to the third group of Bright Wood managers to graduate from Central Oregon Community College’s Leadership Lab for Manufacturing & Construction. They finished the seventh and final session on March 17.

(Pictured left to right) Jose Vargas Villagomez (Prineville Fingerjoint), Scott Schierling (Quality), Keith Housden (Madras Plant 13), Brandon Chandler (Madras Plant 13), Jose Garcia Solis (Madras Plant 11), Jose DePaz (Madras Shipping), William Rickard (Madras Plant 5), Davie Crockett (Materials Planning), Matias Reyes (Madras Plant 8), Tommy Alvarez (Madras Plant 8), Cesar Lopez Moreno (Madras Plant 3), Gerardo Patino (Madras Plant 3), Miguel Gamboa (Madras Plant 16), and Jason Cordes (Madras Plant 5). Not pictured: Brady Greene (Prineville Cutting).

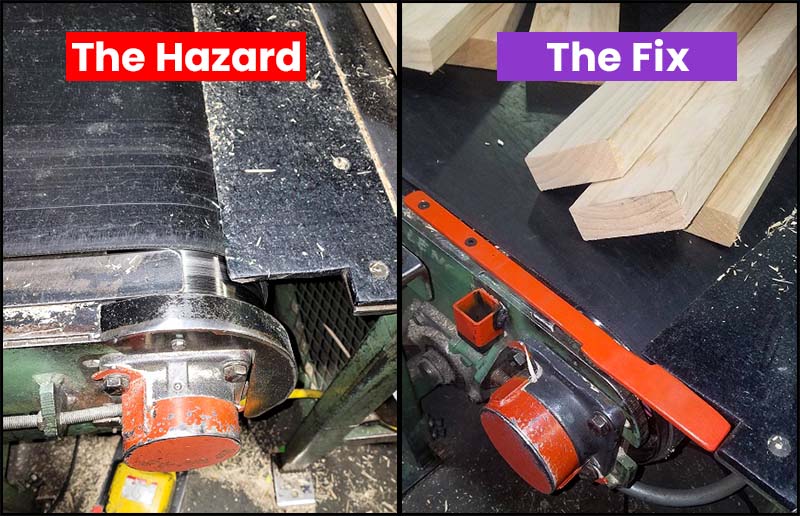

New Tracker Helps People Spot and Eliminate Hazards

[December 13, 2022] More Bright Wood people can see their workplaces with OSHA’s eyes thanks to a new application called the Hazard Tracker. “The tracker is a great teaching and training tool,” Jim Sanders, Madras Safety Manager, said. “You can see what issues OSHA will have. You can also learn how to abate hazards by seeing what other people did.”

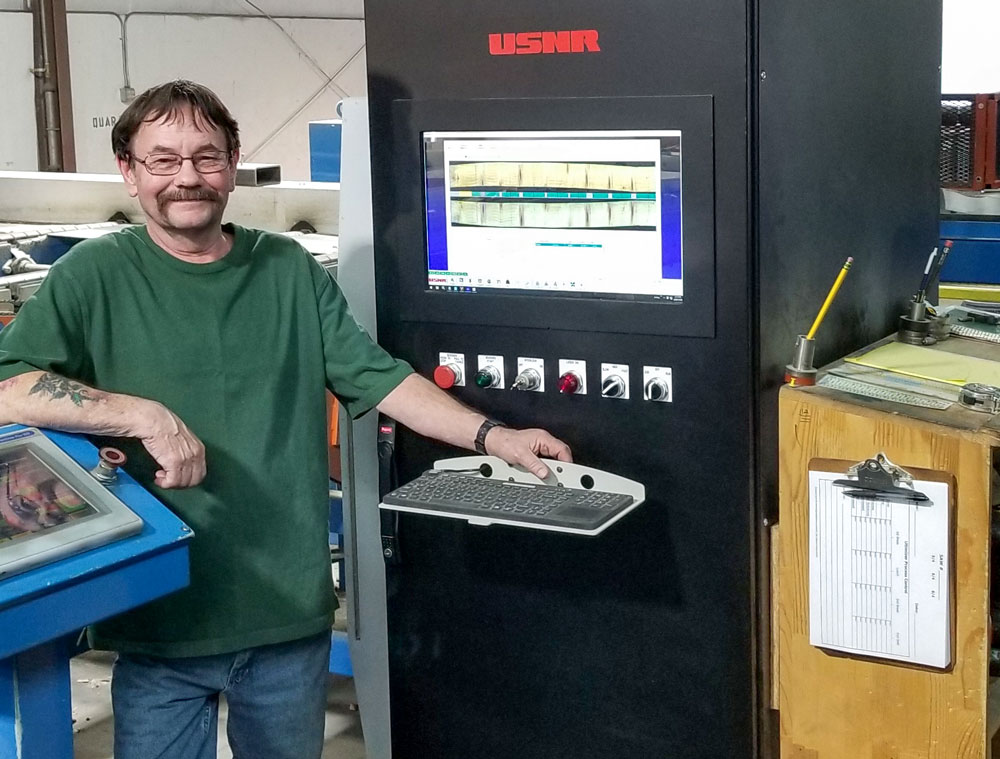

Introducing The New Madras Plant 1

[September 28, 2022] Madras Plant 1 was a shuttered manual rip and cut operation two years ago. Today Plant 1 is a first-of-its-kind optimizing cut plant, with two lines consisting of one USNR scanner feeding two high-speed Ultimizer cut-off saws.

In Memory of Gary Burtis

June 22, 1950 – July 24, 2022

[August 5, 2022] Gary Burtis joined Bright Wood in 1991, starting in the Madras moulding plants. We were sad to see him go when he retired as the lead buyer for the Purchasing Department in 2016.

“Gary was a really good fit as a buyer,” Troy Towers, Purchasing Manager, said at the time. “You must be steady and methodical but also able to react quickly and creatively to changing situations. Gary kept his cool, sense of humor, and focus on what was ethical and best for Bright Wood.”

Our hearts and prayers are with Gary’s wife, Carla, his three daughters, and the rest of his family as we all mourn the loss of an exceptional human being.

Bright Wood Contributes $1.36 Million to the 401(k) Savings and Profit Sharing Plan

[June 29, 2022] Bright Wood people have something extra to celebrate going into the 4th of July holiday. Dallas Stovall, CEO/President, announced on June 28 that Bright Wood is contributing $1.36 million to the Bright Wood 401(k) Savings and Profit Sharing Plan.

The funds will be distributed as a 401(k) match and a profit-sharing contribution.

401(k) Match: Plan participants who deferred a portion of their pay into the Plan received a matching contribution on June 15. “Fortunately, we have a 94 percent participation rate in the Plan,” Dallas said. Bright Wood kicked in 50 percent on the first 4 percent of each eligible participant’s payroll deferrals. Overall, Bright Wood handed out $760,000 in matching contributions.

Profit-Sharing: “In recognition of this year’s hard work and sacrifices, I am pleased to announce that the company will be making a $600,000 contribution to the Bright Wood 401(k) Savings and Profit-Sharing Plan,” Dallas said. “This is in addition to the 401(k) match.”

Profit-sharing contributions will be deposited into Plan members’ Empower accounts during the second quarter of 2022. To qualify, you must have opted into the Plan and have been employed by Bright Wood on December 30, 2021. The funds will be allocated according to each individual’s percentage of the overall payroll.

Bright Wood will have given over $2 million to associates in 2021 through bonuses, 401(k) matching, and profit-sharing contributions. “I want to thank everyone for a successful 2021,” Dallas said. “It was a rollercoaster ride, but thanks to everyone’s continued hard work, we finished with a solidly profitable year.”

Team Cuts a Hole in the Roof to Install Scanner Diverter

[June 10, 2022] Bright Wood installed the first of three scanner outfeed diverter systems in Madras Plant 11. Crews had to cut a hole in the plant’s roof to lower the 4,500-pound Ultimizer diverter into position.

The diverters are for three new USNR deep learning artificial intelligence scanners. One scanner is in, and the remaining two scanner/outfeed combinations will be installed within the next couple of months.

Our Longest Engineered Dimension Lumber Yet

[June 2, 2022] Big day at the Culver site. Today the engineered dimension lumber operation ran the longest product yet for Bright Wood. The 53’6” long Douglas fir 2" x 10" material is headed to Wisconsin, where it will be used for barn rafters.

Culver’s long-length line has the capacity to run material up to 60’.

Thanks to Jesus Cohetzaltitla, Culver Site Manager, for the product photo and Marty Weimer for the two barn photos.

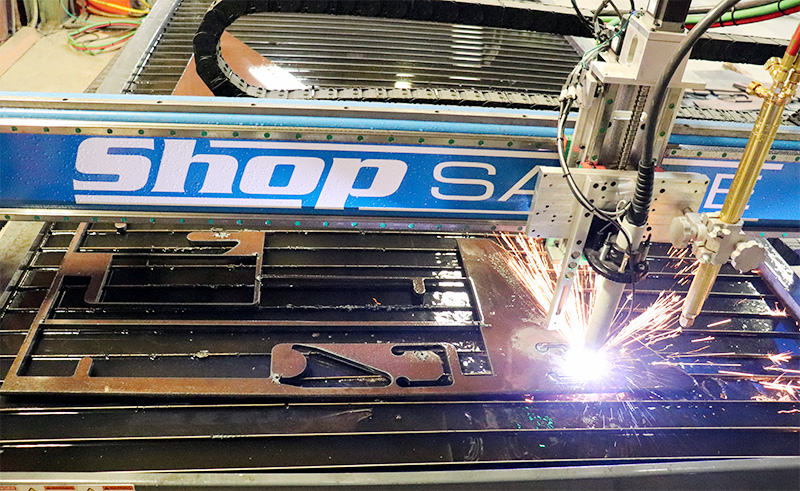

New CNC Torch: New Possibilities for Metal Fabrication

[May 17, 2022] Christmas came early for the Fabrication Department with the arrival of a brand new ShopSabre CNC plasma torch in May. They wasted no time putting it to good use building conveyor parts for a new line in Madras Plant 1.

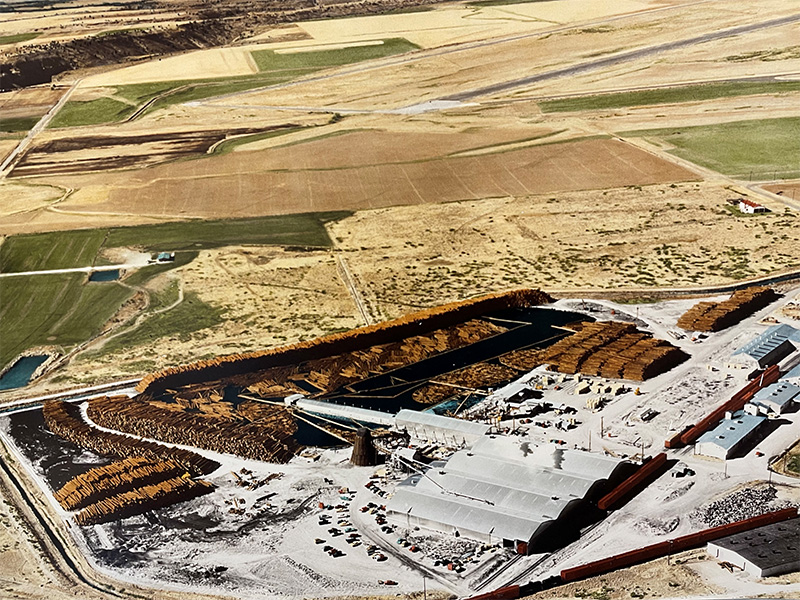

Notice Anything Familiar in this Photo from the Early 1960s?

[Updated July 26, 2022] The building we know as Madras Plant 7 started as the Jefferson Plywood Company in 1957.

Built by Sam Johnson, it was the first Oregon plywood plant east of the Cascades. Johnson was the third generation of his family to be involved in the wood products industry, and he would go on to serve seven terms in the Oregon House of Representatives.

Unfortunately, the site closed in March 1966 after a pre-dawn fire destroyed the football-field-sized loading dock and over 400,000 board feet of lumber. According to one newspaper account, the fire was so large that people over 30 miles away in Prineville could see the glow.

Warm Springs Forest Product Industries, owners of Jefferson Plywood at the time of the fire, eventually moved the plant’s equipment to Warm Springs and constructed a new plywood operation near their sawmill.

Bright Wood purchased the old Jefferson Plywood site in 1987. The building became the home of our first dedicated lamination plant in 1988.

Today Plant 7 is one of Bright Wood’s busiest plants, shipping over 112 truckloads of engineered window and door components per month to some of the most prestigious manufacturers in the industry.

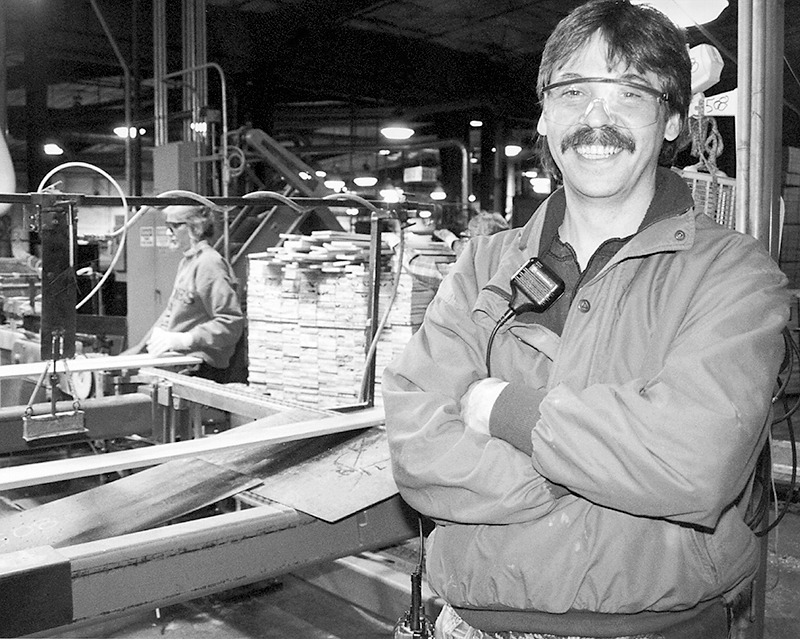

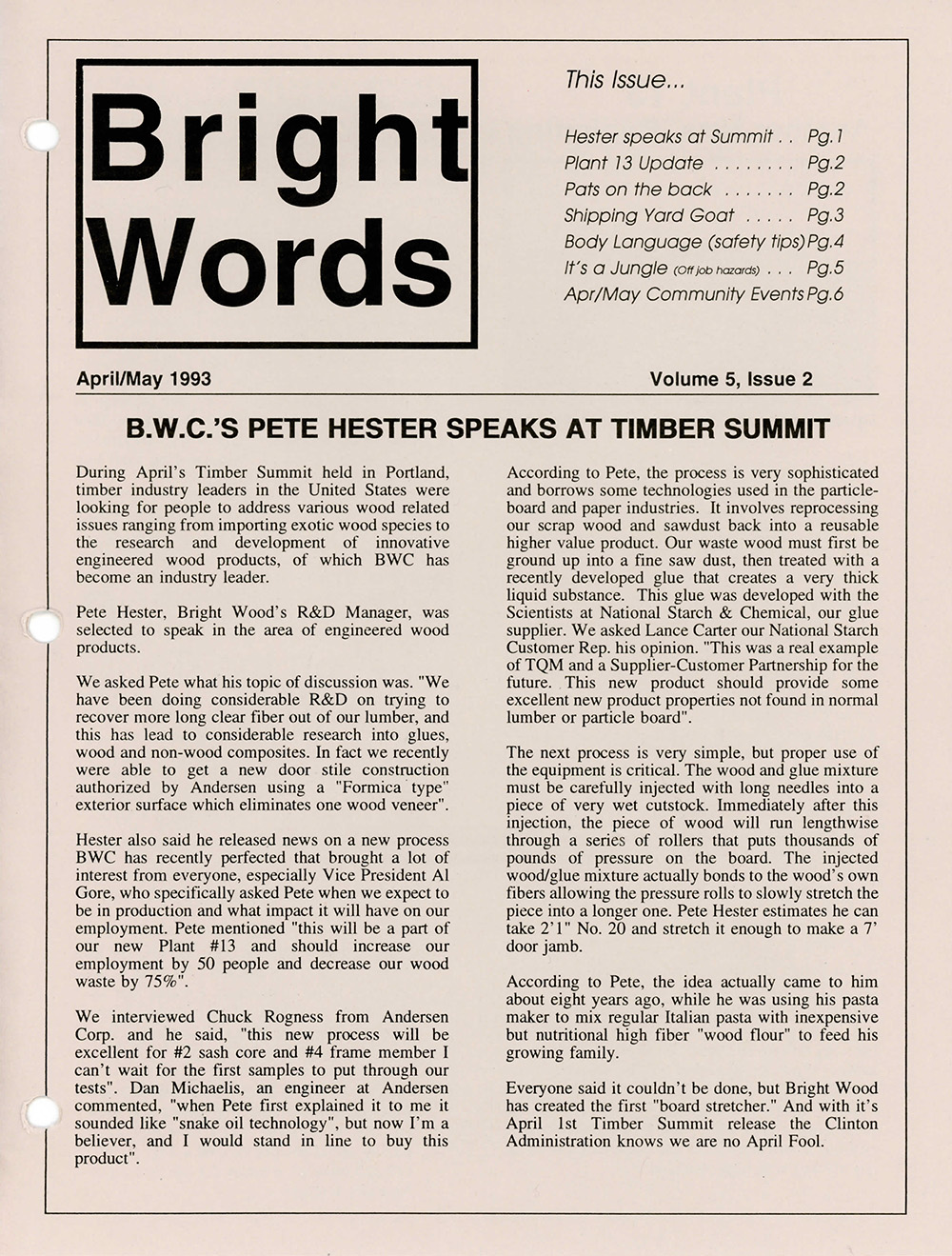

Flashback April 1993

[April 1, 2022] Bright Wood caused a stir when we published this newsletter article about a board stretcher in April 1993. Pete Hester was Bright Wood’s Research and Development Manager in the 1980s and early 1990s. His track record for wood innovations was such that anyone who skipped the last paragraph was VERY interested in the board stretcher.

Pete was also very interested when he read about “his idea” in the newsletter.

Here’s to our innovators … and our pranksters. You make Bright Wood one of a kind. Happy April Fools Day!

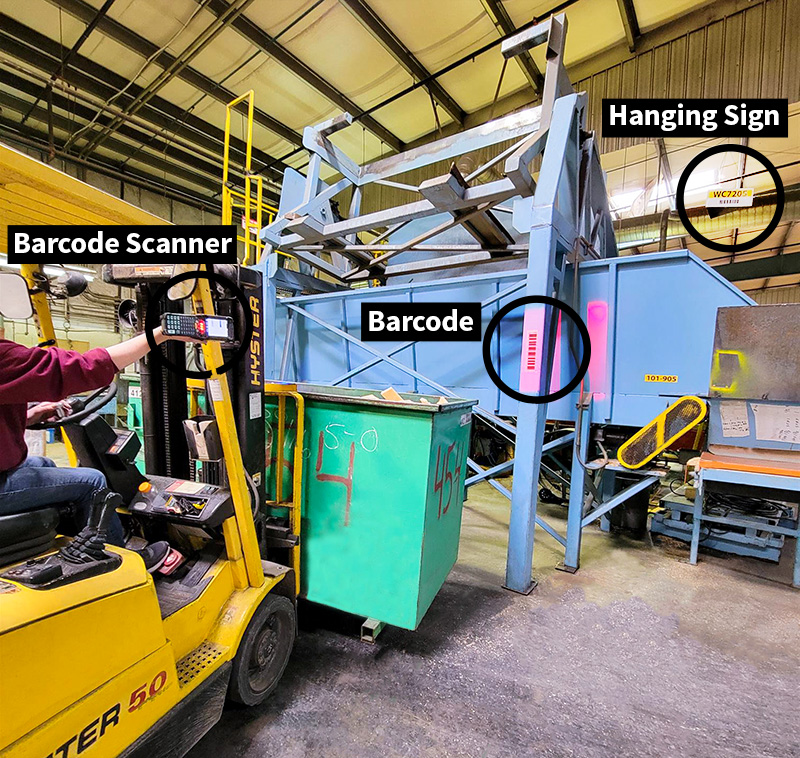

New Location Standards Make Perpetual Inventory Possible

[February 15, 2022] Today’s world-class companies are masters at collecting, sharing, protecting, and using data. They plan better, react faster, and operate more efficiently than competitors because they see the true, real-time picture of orders, inventory, production, the marketplace, and more.

The new Data Governance Council’s (DGC) job is to make Bright Wood world-class at getting the most value out of its data. It is a big job, so the DGC began with Bright Wood’s location data.

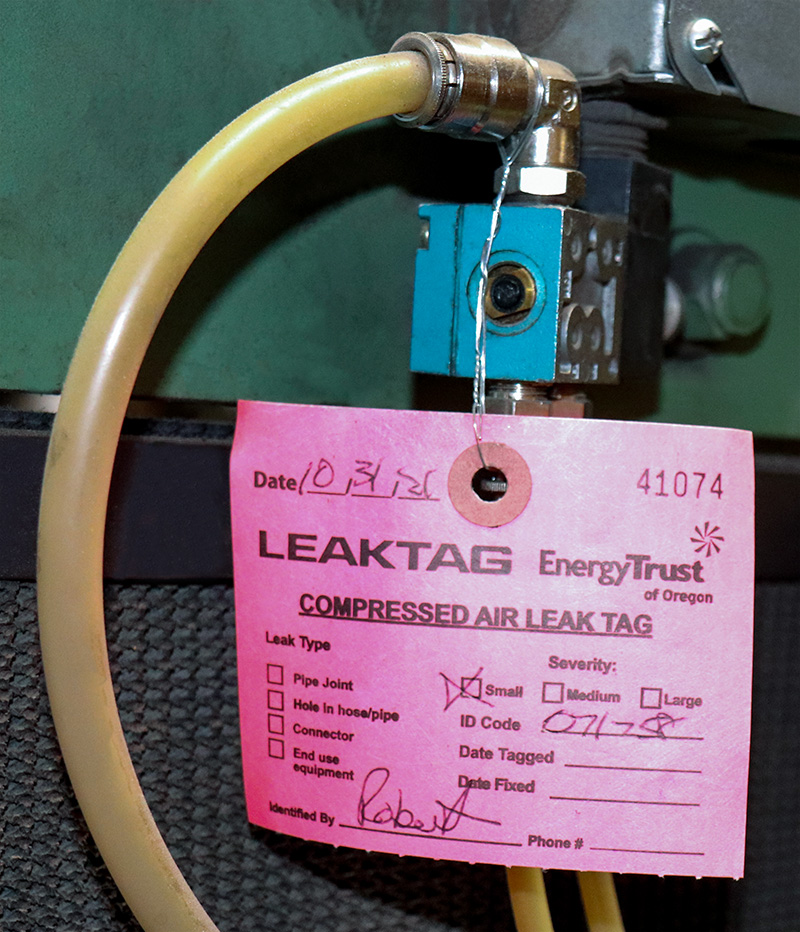

Compressed Air Audit Reveals Big Savings

[February 1, 2022] One Friday night in October, they shut everything off at the Redmond site, and everyone went home for the weekend. Sunday morning Redmond Maintenance Manager Robert Palmer and Slicing Supervisor Matt Bigness turned on the air compressors.

Then Robert and Matt went for a walkabout with Kelly Brown and Kevin Collins of the Strategic Energy Group to find air leaks.

“When you walk into a quiet building, you can hear the leaks,” Robert said. “You follow the sound.”

How Bright Wood Responded to a 2017 OHSA Inspection

[November 2, 2021] Oregon OSHA safety compliance officer Jarrodd Bohn arrived unannounced at Bright Wood’s Redmond, Oregon facility on Nov. 20, 2017, to conduct the first comprehensive plant inspection in 20 years. Read what happened next in OSHA’s 2018 Grassroots Report.

Madras Plant 1 Reborn as an Optimizing Cross-Cutting Plant

[September 1, 2021] Madras Plant 1 is back as an optimizing cut plant. Crews gutted the old manual cut plant last year and extended the building. The new highly nimble cross-cutting operation removed their training wheels in June.