New CNC Torch: New Possibilities for Metal Fabrication

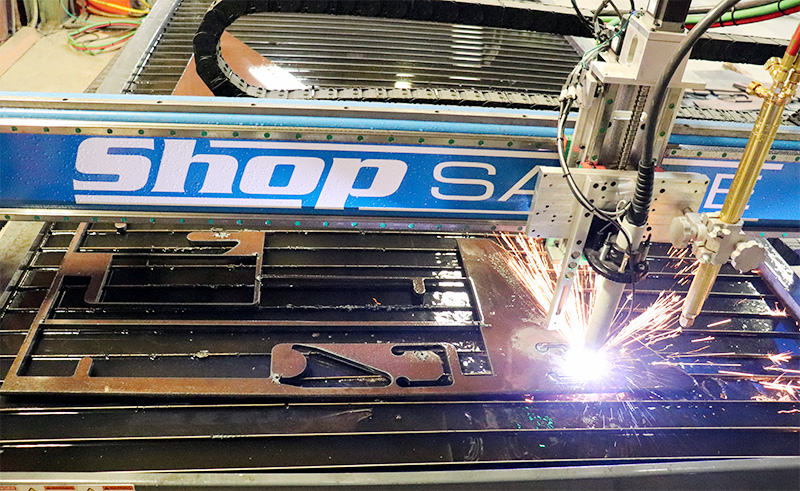

[May 17, 2022] Christmas came early for the Fabrication Department with the arrival of a brand new ShopSabre CNC plasma torch in May.

The CNC torch is a critical piece of equipment for the Fab Shop. They use it 20 to 30 hours every week to make parts for in-house-built machinery and systems. CNC stands for “Computer Numerical Control,” which means that a computer program guides the torch to cut a pattern out of a metal sheet.

Bright Wood built its own CNC torch in the mid-1990s, but this time around, the Fab Shop decided to purchase one from ShopSabre, a manufacturer in Lakeville, Minnesota.

“The new torch will burn a 16-gauge plate in about 280 inches per minute,” Steve Ankrum, CAD Designer, said. “It is extremely fast compared to our old one.”

The old and new torches handle approximately the same size of metal sheets, but the new plasma torch can burn through deeper material up to 1”. A second oxy-fuel torch can handle thickness up to 12”.

“We used to have to manually raise and lower our torch to make the cut, which was a pain on wavy metal,” Steve said. The new system automatically adjusts the gap between the tip of the torch and the metal plate to keep it within a target voltage set by the programmer.

The new ShopSabre’s finished-cut quality and speed are time-savers for Fabrication. “We also have a marking system add-on that will improve layout quality and reduce labor costs,” Steve said. “And once we prove the marking system, we can also add a drill to the CNC that will decrease consumable costs and labor.”

“We are looking forward to all the possibilities this ShopSabre offers,” Steve said.