New Location Standards Make Perpetual Inventory Possible

[February 15, 2022] Today’s world-class companies are masters at collecting, sharing, protecting, and using data. They plan better, react faster, and operate more efficiently than competitors because they see the true, real-time picture of orders, inventory, production, the marketplace, and more.

The new Data Governance Council’s (DGC) job is to make Bright Wood world-class at getting the most value out of its data. It is a big job, so the DGC began with Bright Wood’s location data.

Location Is Everything

“The existing location data just evolved,” Kevin Stovall, Vice President, said. “Location information has become far more complicated and complex as we have added sites in Redmond, Menomonie, Prineville, and Culver.”

“Manufacturing and Support Services have had similar, but not necessarily identical, ways of identifying locations, equipment, plants, etc.,” Kevin said. “The systems we have been using have worked okay, but we need a more logical and comprehensive approach if we want to grow and better serve our customers.”

“The best example of how location data impacts our ability to serve our customers is in Menomonie,” Kevin said. “We hold an inventory with tens of thousands of part numbers. We ship to multiple customer locations, multiple times a day, in precise quantities, and in many cases specifically sequenced to exact machine centers ready for assembly.”

“The Menomonie warehouse would be impossible to manage without a nearly foolproof method of knowing what part numbers are where,” Kevin said. “Multiply the complexity of Menomonie by the volume of transactions here in Oregon, and poor location data would very negatively impact our business.”

Everyone Uses the Same Ids

“Creating a standardized location structure that meets the needs of all the parts of the business allows us to incorporate these locations into all of our systems,” Kevin said. “This will help ensure that we have accurate data so that we have a very high degree of confidence in our decisions.”

Prineville Is Square One

The DGC chose Prineville as the test site. “Prineville is a good representation of our production processes and is small enough to test the solution efficiently,” Brian Winters, FACTS (Financial Accounting Cost Tracking System) Project Manager, said. “A good pilot program provides a platform for the organization to test logistics, prove value, and reveal deficiencies before spending significant time, energy, or money on a large-scale project.”

In November, Robert Palmer, Redmond and Prineville Maintenance Manager, and his team installed over 70 signs for Prineville’s plants, work centers, areas, sheds, and warehouses. The new signs may look like a simple change, but a lot of work went into them.

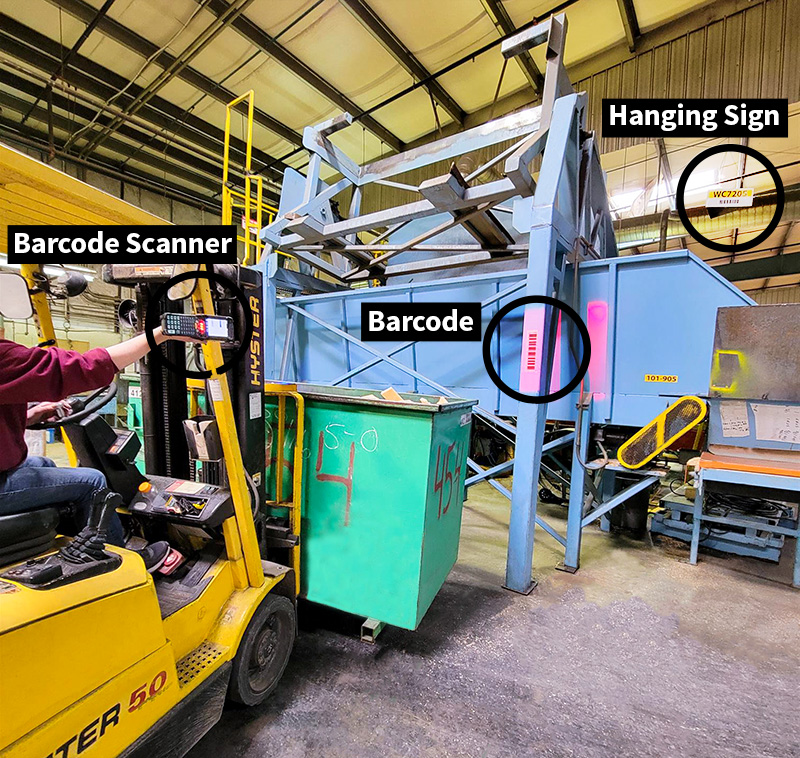

“The new location signs result from establishing location standards as well as governing location data,” Brian said. “The signs for locations where we have inventory also have barcoded labels we will scan as we move inventory units from and to various locations.”

“Location data is a critical component to inventory management,” Brian said. “Without quality location data, inventory management is inefficient, inaccurate, and costly. High-quality location data is critical to successfully implementing a perpetual inventory solution.”

Perpetual Is Now Possible Companywide

“The Location Data project is just one of many projects that are an outgrowth of Project FACTS,” Kevin said. “Along with implementing location data, Prineville will be the test site for our Perpetual Inventory Project (PIP).”

“PIP will eventually allow us to see a live inventory of all of our units,” Kevin said. “This one project will be the stepping-off point where a number of the Project FACTS projects can now begin to be implemented.”

“Project FACTS and all the associated projects that go along with it will be the most important projects we have ever implemented at Bright Wood,” Kevin said.