Redmond Compressed Air Audit Finds Big Savings

[February 1, 2022] One Friday night in October, they shut everything off at the Redmond site, and everyone went home for the weekend. Sunday morning Redmond Maintenance Manager Robert Palmer and Slicing Supervisor Matt Bigness turned on the air compressors.

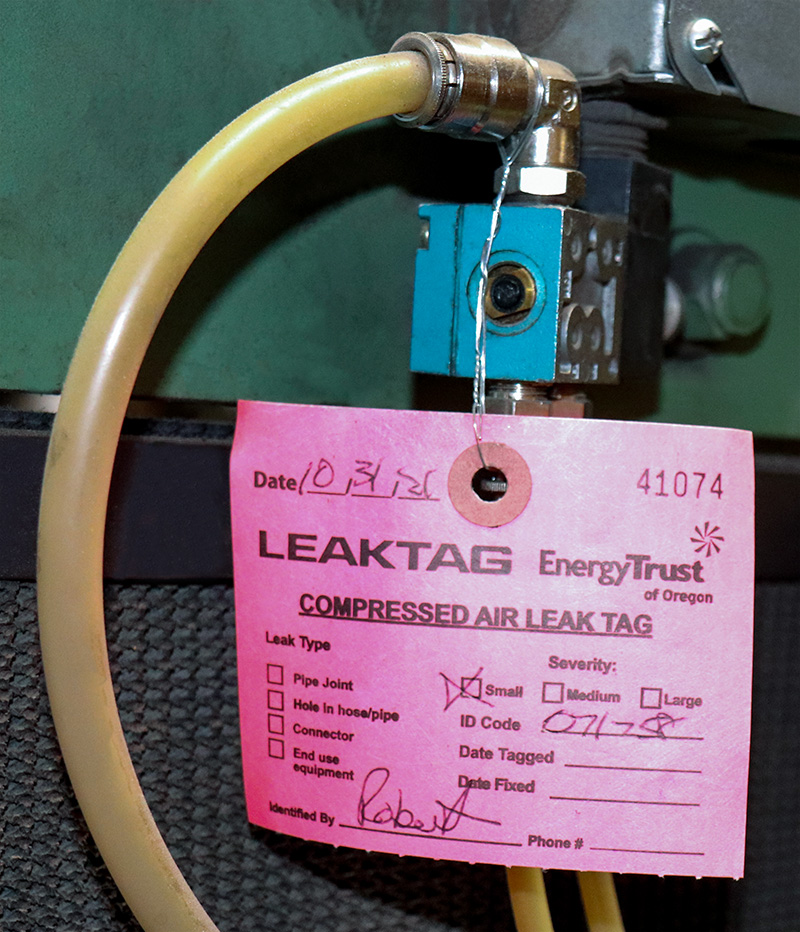

Then Robert and Matt went for a walkabout with Kelly Brown and Kevin Collins of the Strategic Energy Group to find air leaks.

“When you walk into a quiet building, you can hear the leaks,” Robert said. “You follow the sound.”

69 Leaks Found = $16,886 Saved Annually

The team found 69 air leaks over three hours. Fixing those leaks will save the Redmond site over $16,886 annually on its utility bills and put them at 118 percent of their 5 percent energy savings target for the year.

“The expense of compressed air is often underappreciated,” Kelly said. “A single large leak can easily cost $500 to $1000 per year. A compressed air audit provides opportunities to increase production while at the same time reducing operating costs. You save money by repairing leaks and minimizing or avoiding inappropriate uses of compressed air.”

The seven large leaks found during the audit have been repaired, and Redmond Maintenance is now working on the medium to small findings.

A Learning Experience

“It was a learning experience,” Robert said. “I didn’t know there would be that many leaks; I was surprised. Most of the leaks were easy to identify, even the small ones.”

“In a few cases, you could hear the leak, but you couldn’t find it,” Robert said. That is when the Ultraprobe the team borrowed from the Preventative Maintenance Department came in handy. “We could hear a leak inside the Wintersteiger reciprocating saw, but we couldn’t pinpoint it,” Robert said. “The Ultraprobe pointed us to the spot.”

“Most of the leaks were in the ¼” tubing, and most of those were fittings,” Robert said. “We’ll be methodically replacing air nozzles, fittings, and tubing as we get the time, even the ones that aren’t leaking now because eventually they will.”

All Eyes and Ears on Air Leaks

“We will teach operators and leads how to repair their leaks,” Robert said. “Most of the time, it is an easy fix that only takes seconds.” A new Air Leak Repair cabinet in the Maintenance Shop will be stocked with replacement tubing, fittings, and air nozzles.

“If you have a leak or a kinked line, don’t just keep going,” Robert said. “Let’s fix it.”

“Air leaks will be an ongoing issue, so report any that don’t have a tag,” Stan Webb, Redmond Site Manager, said.