Multiple Supply Chain Issues Upend Business as Usual

[February 18, 2022] The past 18 months have been a balancing act for Bright Wood. On one side, strong demand; on the other, supply chain issues. In the middle, Bright Wood people figuring out how to get the job done in new ways.

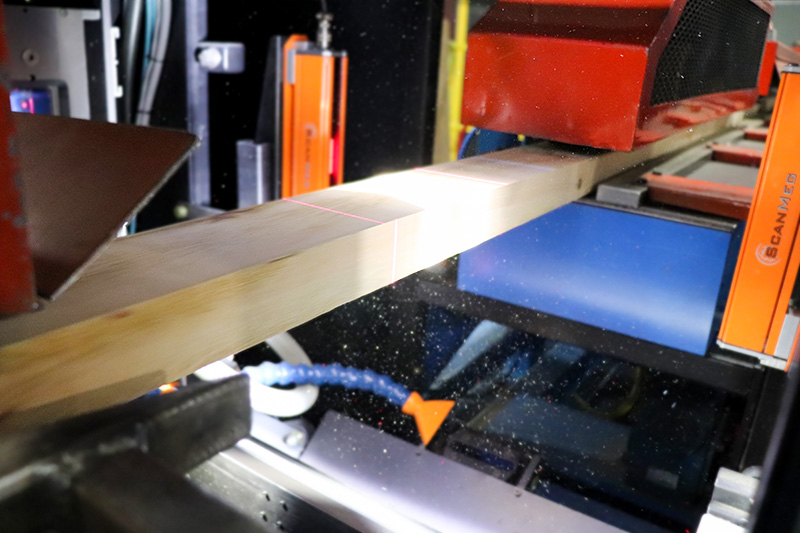

Tight Supply

“Domestic lumber availability has been constrained due to labor shortages, and more recently, harvest restrictions due to rough fire seasons in both 2020 and 2021,” Carl Lindgren, Industrial Sales, said. “Many mills will be forced to cut logs from these fire sales well into 2022, and this means that getting the grades and sizes we need to operate our plants will continue to challenge the business.”

“Imported lumber has been plagued by a shortage of containers, a lack of capacity on ships, and trucking capacity,” Carl said. “This has led to significant disruption in the ability of Bright Wood to get all the material we have ordered. Many speculate that the logistical bottlenecks we face today with imports will last all of 2022.”

“Bright Wood has managed to ship products to our customers by being incredibly flexible and adaptive in the face of this adversity,” Carl said. “We’ve incorporated new species, sizes, and grades into our raw material supply. Many of the new sources have required changes in our operation to convert this material into the products our customers need. Thanks to everyone for their creativity, flexibility, resilience, endurance, and patience during these tough times!”

Longer Lead Times and Higher Prices

Bright Wood has used that same flexibility and adaptability to handle other shortages as well. “We are seeing longer lead times for purchased parts such as bearings, sprockets, motors, valves, etc.,” John Carson, Fabrication Manager, said. “Items that our vendors stocked in the past and would arrive in a few days can now be two to six weeks out.”

“The area where I have seen the biggest change is steel costs,” John said. “In just one year, sheet is up 134%, tube is up 102%, plate is up 106%, and angle is up 55%.”

“Steel pricing has affected fire suppression parts so much that pipe delivery has been pushed out and sometimes rationed out,” Steve Kenison, Facilities and Truck Shop Manager, said. “Materials for steel buildings have been delayed and some we can`t get. If I ordered a new building today, I would see it in September 2022, hopefully.”

“Overhead doors parts – especially springs – are our biggest item that we cannot get right away,” Steve said. “The doors we took out when we installed the new high-speed doors have been repurposed and cut down for repairs.”

“New forklift delivery times are a year out at best,” Steve said. “Forklift leases and rentals are not being returned, taking away our chances of getting one of those. Meanwhile, the used market is almost nothing. If a used machine does become available, it is sold before the dealer can service it.”

“We’ve had newer machines down for months because common parts are back-ordered to the factory and unavailable,” Steve said.

Bright Wood’s Purchasing Department is on the frontlines. “We’ve been in a constant state of scramble with 10 to 20 new supply issues coming up every week,” Troy Towers, Purchasing Manager, said. “Today we’re dealing with a spray can shortage, which affects everything from degreaser to paint.”

Bright Wood has adapted by stocking more common parts in-house and asking vendors to increase their inventories. “When we can, we replace one brand with another,” Troy said. “The valves we’ve used on our glue accentuators for years are not expected to be back in stock until February 2022 at the earliest, so Bright Wood switched to another manufacturer’s valves.”

Bright Wood has also had to make do. “When the quick disconnect cords we use on every motor at Bright Wood became unavailable, we reverted to hardwiring motors,” Troy said.

An Inside Job: Bright Wood Makes Its Own

“To Bright Wood’s credit, we’ve dodged some shortages by having in-house capabilities that other manufacturers are just now investing in,” Troy said. “Our Fabrication Department, Machine Shop, Rebuild Center, and Saw Shop supply us with essential services and parts like shafts, chop saw guards, and squeeze-block components so we don’t have to rely on anyone else.”

“The Preventative Maintenance program Bright Wood started in the early 1990s has helped us avoid breakdowns that would have left us scrambling to find critical parts,” Troy said.

With no end to supply chain issues in sight, Bright Wood people are focused on what we can control. In the words of Robert Schuller, “Tough times never last, but tough people do.”